Aftermarket Wheel Size Guide

Choosing new wheels for your vehicle can be done for a variety of reasons. Wheels come in many different sizes and styles depending on what your needs are. When purchasing new wheels, there are all kinds of labels and specifications to help you choose the right wheel for your vehicle.

This article isn’t designed to be a guide on how to fit specific wheels to your vehicle, as every vehicle is different, this is more of a guide on understanding the way wheels are labelled, and how they’re not all just round rubber things under your car.

As always, ensure that you follow your state regulations when it comes to aftermarket wheel sizes as each State and Territory has their own rules to determine how big, how wide and how aggressive offset your new wheels can be.

Diameter

When talking about wheels, everyone knows about wheel diameter. This is a measurement across the whole wheel from one side of the tyre seat to the other. The total wheel diameter is from lip to lip and will read higher than the stated diameter.

Upgrading to a larger diameter wheel can be done for a variety of reasons including style and performance upgrades (a lower profile tyre will generally have a stiffer and more predictable sidewall, to a point).

Larger diameter wheels will often weigh more than smaller diameter wheels, everything else being equal. There are exceptions to the rule, no doubt there exists crazy forged carbon 19”s that weigh less than most 17” stockers. Heavier wheels typically result in doughier handling, slower steering response and dull suspension feeling, as they struggle to cope with the extra unsprung weight.

Likewise, changing out your current wheels for a smaller diameter can also be done to make the vehicle more suited for specific use. Some 4WDs come standard with huge alloys while the driver may prefer a smaller steel wheel with a much larger sidewall designed for off-road use.

Width

Just as wheels come in various diameters, there are different widths as well. Generally, the wider the better when it comes to handling until a certain point where weight becomes an issue. Wider width wheel and tyre combinations can add significant unsprung weight that can have detrimental handling effects.

Going too wide on a light car can cause the vehicle to aquaplane as it just doesn’t have the weight to push the tyre down through standing water on the road. A wider tyre has a larger contact patch which takes longer to disperse water than a smaller width tyre.

Going extremely wide of a wheel and tyre combination can also have detrimental effects on handling. In some situations we’ve seen a super wide wheel have so much grip on the outside of a vehicle in turns that the vehicle will lift the weight from the inside tyres, causing a loss of grip and cornering speed when compared to a wheel and tyre size more suitable for the vehicle.

Running too narrow a tyre on a wide rim can cause your tyre to have a stretched look. Running a stretched tyre can impact handling negatively in a few ways, however, your drifter friends will love how much more aggressive the handling responsiveness will be.

Running stretched tyres can also put your tyre beads at risk of coming unseated and causing an accident, as well as putting your rims in harm's way from curbs, stone chips and other physical damage.

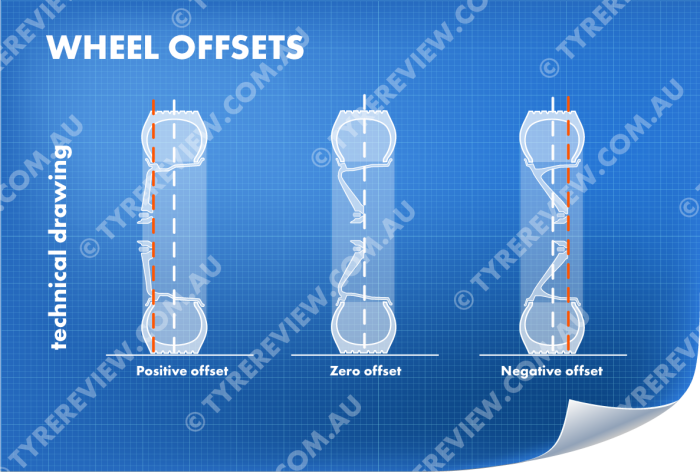

Offset

Offset is the measurement of where the wheel sits in relation to the centerline of the wheel. Negative offset will push the wheel outwards from the vehicle body, while a positive offset (as is common on most stock wheels) will pull the wheels further back under the car, ‘inside’ the bodywork.

Almost all factory fitted wheels have a positive offset.

If the mounting surface of the wheel is exactly halfway between the inner and outer lip, it is described as a zero offset wheel.

If the mounting face is biased towards the face of the wheel, that wheel is a positive offset and likewise, if the wheel mounting face is biased towards the rear of the wheel, that wheel is likely to have a negative offset.

Scrub radius

Changing to an aftermarket wheel with a much more aggressive offset than your standard set can possibly introduce an effect called steering scrub. Read about the effects of scrub radius in our wheel alignment article.

Wheel spacers

This is where wheel spacers come into play. Wheel spacers could be an article unto themselves, but the gist is, it is possible to ‘fake’ having a lower offset wheel with the use of spacers to push the wheel further outboard.

For example, a +12 offset wheel will have the same fitment to a -8 offset wheel with the use of a 20mm spacer. However, it’s worth noting that the use of wheel spacers on vehicles in Australia is illegal unless fitted from the factory. Some Porsches, for example, use factory spacers to retain the same wheel design with larger brakes.

Wheel spacers are mainly used for aesthetics or possibly to solve brake and suspension clearance issues. Even when using a good quality brand they can still cause additional wear and tear on the hub and bearing (similar to how aggressive offset wheels can) and lower quality spacers can crack or break leading to dangerous failure, as you’ll discover online if you look up wheel spacer failures.

It may be possible to get a modified vehicle engineered to run a wheel spacer, however in most cases it’s safer and easier to simply purchase the right size wheel to begin with. Seek advice from the relevant authority in your state before you proceed with wheel spacers vs buying wheels with the proper offset and backspacing in the first place.

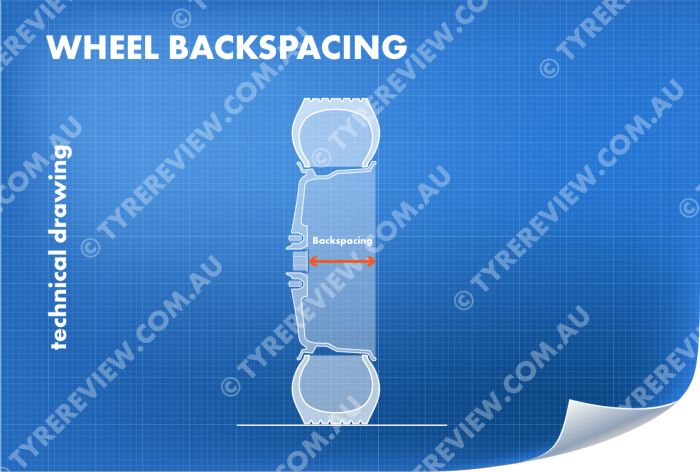

Backspacing

Backspacing is a function of width and offset together. Backspacing is the measurement from the wheel mounting face to the rear most point on the wheel and will tell you how much clearance you need behind the wheel.

Usually backspacing must be considered when fitting much wider wheels than stock and will let you know roughly how much clearance you will need to have behind your wheel for important components like suspension arms, chassis rails or springs/shocks to clear the wheel.

Backspacing can be measured by holding a straight edge across the back lip of the wheel and taking a measurement from the straight edge to the hub mounting face.

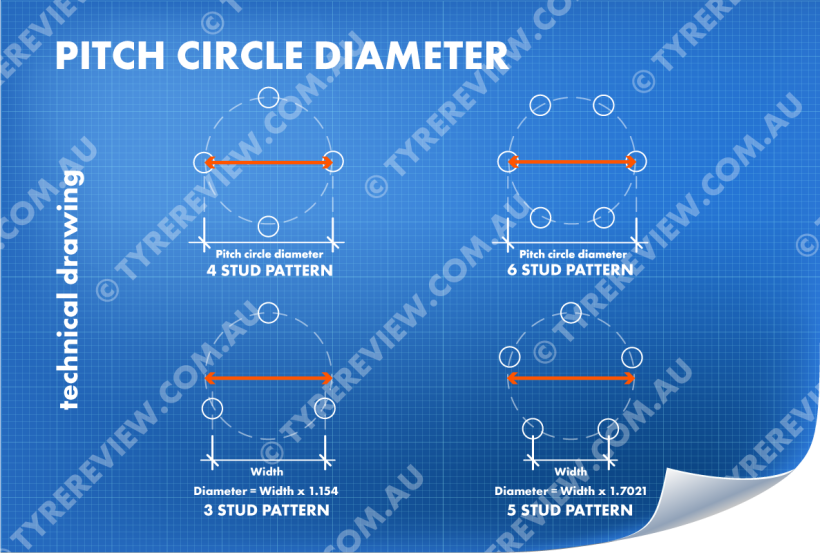

PCD

Short for ‘pitch circle diameter’ this is the label given to the bolt pattern used to hold the wheel onto the vehicle hub. Cars, vans and lighter vehicles are commonly found with 4, 5, or 6 bolt patterns for studs although on rare vehicles other variations exist.

The ‘circle’ referred to here is the diameter of a circle on which the bolt holes are drilled. How many holes depends on the application, however they are always equally spaced around the circumference of this circle.

For example, 5x114.3 means there are 5 holes, spaced equally on a circle that is 114.3mm in diameter.

How to measure PCD?

Measuring your PCD if you have 4, 6 or the increasingly common 8 lug patterns is dead nuts (haha!) simple, just measure the centre of two opposite bolt holes. Bam.

PCDs with an odd number of holes are slightly more difficult but nothing you’ll need an engineering degree for to nut out.

3 stud PCDs are fairly uncommon (found on some old Citroens, Renault, Smart cars) but to find out a PCD, measure from one bolt center to the next bolt center, and multiply the result by 1.154.

5 stud PCDs are found on a majority of vehicles on the road and are by far the most common. As with the 3 stud PCD, measure the center of two adjacent bolts but this time multiply by 1.7021.

Why is my PCD a weird number?

A majority of the PCD standards originated in the United States or in countries that used imperial measurements. Except for those with the devils stud patterns of 4x100 and 5x100, many of the common PCDs you’ll find out in the wild will round off nicely when measured in inches.

For example 6x139.7 is exactly the same as 6x5.5”. And the ultra-common 5x114.3 is 5x4.5” when measured in imperial measurements.

Barrel Profile Type

The outer barrel of the wheel is usually covered by the tyre and rarely seen but it’s a carefully engineered series of straight sections, swaged bumps and curves designed to maintain optimal strength and tyre seating performance.

Some tyre variations specify a particular type of barrel. The most common wheel barrel type on modern passenger vehicles is the H2 wheel.

Certain run-flat tyres are examples of tyres requiring the inner two security humps found on EH2 and EH2+ wheels. In the event of being driven on while severely underinflated, the extended humps found on EH2 series wheels counteract the tendency of a deflated tyre to roll off the bead into the centre of the wheel.

We’ve added a diagram showing a massively overexaggerated example of the differences between barrel profiles. In reality, the differences are smaller and less obvious without looking at the markings stamped on the wheel itself.

Generally, your tyre shop will advise if you’re fitting the wrong tyre to a wheel, but the entire ecosystem of wheels and tyres on passenger vehicles is fairly standardised so you’re unlikely to come into any issues unless dealing with very old or exotic models.

Tyre Bead Profile

On all wheels, the wheel flange is specified too (the flange being the outermost edges of the barrel profile). Signified by a letter, in most cases the letter will be B for older, smaller wheels (commonly 12” and smaller), J for almost all modern passenger cars and JJ for some 4x4 and SUV tyres.

Heavy commercial vehicles, as well as vehicles for offroad use and construction equipment, will have different styles of bead profile to suit those applications.

You must not fit a tyre to a wheel with an incompatible bead profile. Doing so may result in the tyre bead unseating, air leaks due to a perfect seal not being made between the tyre and the wheel, as well as tyre or wheel damage during the mounting process.

Some other bead profiles you might encounter:

- A - Bicycles, Motorbikes, Forklifts

- B - Old wheels less than 6” wide (it is not permitted to fit a J profile tyre to a B profile wheel)

- D - Bicycles, Motorbikes, Forklifts

- E, F, G, H are typically found on heavy duty applications such as trucks

- J, JJ - Found on modern road-going cars, 4WD and SUVs

- W - Tractors

There are a few other variations but if you’re wanting to make sure what wheel you have, you can find the information stamped on it somewhere, usually on the back of the spokes, depending on the design.

Certification

Wheels and tyres cop a lot of abuse in the way of potholes, speedbumps, driveways, curbs, off road impacts, rocks, the list goes on.

Many of the big wheel manufacturers go through extensive testing and certification so that customers can ensure the aftermarket wheels they purchase are as strong, if not stronger, than the factory wheel being replaced.

Being strong isn’t the only goal here. High quality and original alloy wheels (forged, flowcast, cast - it doesn’t matter) will tend to bend or change shape in the event of an accident in an effort to absorb heavy impacts, while cheaper castings can suffer critical failure by way of cracking, breaking into multiple pieces and failing suddenly. The type of failure could mean the difference between retaining control of the vehicle or not.

Some of the most common marks you will see on wheels certified for road use are JWL, VIA, TUV and SAE.

The differences between them all, and how strict the testing and certification procedures are, is an article for another day, but any brick and mortar tyre and wheel shop will be able to tell you what certification is on the wheels they sell.

If you’re buying wheels online, double-check that you’re not getting cheap replica wheels made with inferior manufacturing techniques, after all, the wheels (and the tyres mounted on them) are the only thing keeping your vehicle in control and shiny side up.

Summary

Using all the knowledge discussed here and looking at a wheel labelled with the following markings:

17x8J +12 5x114.3 JWT/VIA we know that this wheel is:

- 17” in diameter

- 8” in width

- A ‘J’ type bead seat, designed to work best with passenger vehicle tyres

- +12 offset, meaning that the wheel has a reasonably aggressive offset

- 5x114.3 bolt pattern, this wheel has 5 bolt holes in a common size PCD, more than likely for a passenger vehicle

- JWT/VIA, this wheel was likely manufactured in Japan and has been tested by the manufacturer to ensure the design meets strength, metallurgical and durability requirements as well as being independently tested. This wheel is approved for road use in areas that acknowledge the VIA certification.

Armed with this knowledge, you can now go out into the big world and get some aftermarket wheels with the toughest fitment you can *ahem* legally fit to your vehicle. Be sure to attach photos to the reviews that you leave for your tyres too.

PRESSURE TEST: DRIVING ON SANDAT OR MT TYRES ON SAND, WHICH IS BEST?Which type of 4WD tyre should I get?Tyre DeflatorsHow to Drive in the Snow - We asked an expert!4wd Air pressure

When do I need new tyres?What should my tyre pressure be?How can I tell what size my Tyres are?Where is my vehicle placard?Wheel Balancing: What It Is and When Your Car Needs ItWheel BalancingSpace Saver vs Full Size Spare TyresOverloading your 4x4 - it’s easier than you think..Vehicle Inspection Schemes across Australia.What should I do if I get a flat tyre while driving?How a tyre's tread pattern deals with waterAquaplaningMaterials used to construct a tyre

What should my tyre pressure be?The Effects of Over or Under Inflated TyresIs filling your tyres with Nitrogen worth it?Advantages of Correct Inflation PressureHow often to check Tyre PressuresNitrogen in tyres